Recommended Steps to Ensure Optimal Machine Performance;

To maintain optimal performance of your Steam cleaner there are 3 key areas to keep in mind and some easy steps you can take to minimise any potential future problems;

1. Water Quality

It is important to ensure that only clean water is used – Only use water that is free from any sediment, detergents, oils or other contaminates. If you are unsure about your available water, contact Steam Australia.

2. Accessory Maintenance

We recommend that all accessories are visually inspected prior to use checking for general damage, please refer to machine specific user manual for more details. Always clean your tools, hose and waste bucket after use. Steam clean tools for quick and easy cleaning, a soak or scrub where required. Ensure to check filters, regularly clean and replace when required.

3. Boiler Maintenance

Water that goes through the boiler contains minerals that over time, solidify to the insides of the boiler causing a limescale build-up. Whenever scaling occurs, the boiler may not perform optimally and may produce excessively wet steam, or in some cases damage to the components inside the machine. To ensure your boiler is functioning optimally it is important to only use clean water inside the machine. We recommend draining the boiler every few months (depending on frequency of use and water quality) to remove excess build up of scale and any impurities. Contact Steam Australia if you have any questions about this process.

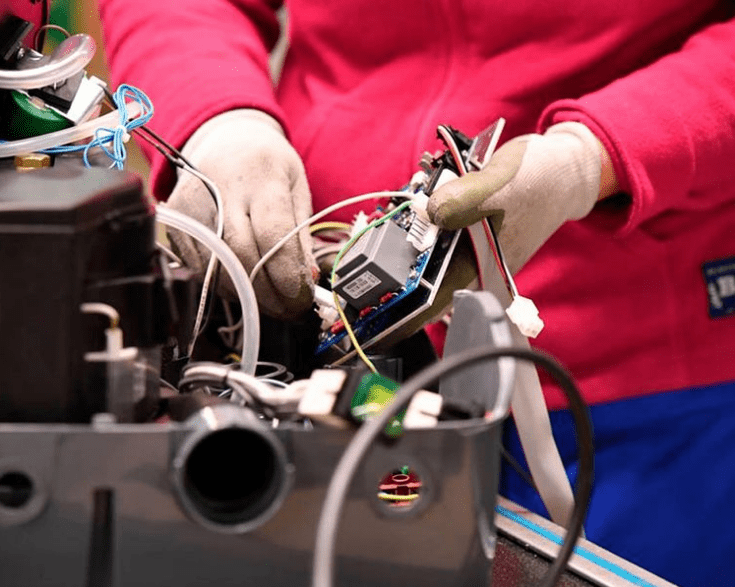

Service Intervals

Service intervals for your machine will depend on water quality and machine usage. There is minimal user maintenance required however we do recommend that the machines are serviced by an authorised service facility at least once every 12-18 months. Refer to the machine specific User Manual and User Guide for more details.

Find your nearest service agent.