Dry steam cleaning is a cost effective and time saving cleaning method removing up to 99.9% bacteria and pathogens. Small or Large, all production facilities can benefit from the improved cleaning results provided by the use of dry steam. From processing to packaging, ensure that infection control and visual cleanliness is always at its best for your workers and consumers.

Make tricky and labour intensive cleaning jobs easier in your facility, with our powerful dry steam sanitising machines.

Whether you require a custom steam tunnel to shrink wrap security seals or you need a custom steam belt cleaner during production, Steam Australia can help select the correct steam machine for your needs.

Single phase machines are common place in many facilities. They are the go to machine for most cleaning tasks due to their high mobility and ease of use.

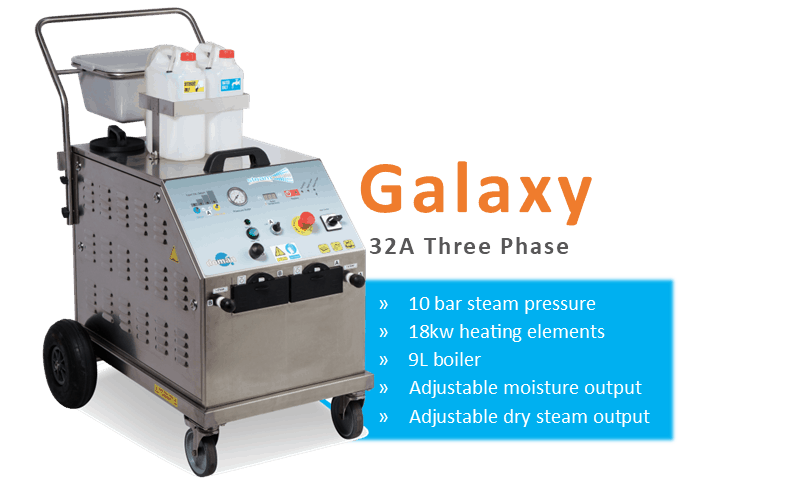

Steam Australia’s 3 Phase industrial units are built to your needs. Whether you are looking for a customised belt cleaning setup or improving efficiencies through detailed lance work – our machines can handle any task.

Why Dry Steam Cleaning?

Economical

Easy & Efficient

Environmentally Friendly

We recommend the following machines from our range for

Food Production and Manufacturing applications.

FAQ's

Are there any PPE requirements?

If cleaning is being performed in an area suspected of being contaminated with the virus the appropriate PPE should always be worn. Introducing a steam cleaner does not require additional PPE.

Can steam vapour aerolize pathogens?

No, the research does not support this. Our machines reach >170°C. Both Monash Health and the NHS in England have tested dry steam to see if it can spread anything. They tested this by sampling the air, vapour and additionally placed settle plates around the room and found that the steam did NOT spread anything.

Can our dry steam units kill COVID-19?

Professor Bloomfield from UNLV says “to actively kill the virus you need temperatures of around 60 degrees [Celsius]”. Our machines are heated to >176°C drastically reducing the contact time required.

Steam is also the recommended process for sanitising a viral agent of any soft furnishings or carpet by the Australian Government and specifically against COVID-19 by the United Kingdom Government.

Can I use any microfibre?

No. You should always use a microfibre cloth proven to remove at least 99.9% of micro-organisms. Most microfibre commercially available do not meet these standards.

Disposable microfibre is always recommended in the case of an infectious organism.

Steam Australia can supply suitable microfibre which has been proven within hospitals for use with our machines.

Who recommends steam cleaning?

The Australian Governments guidelines provided by the CDNA recommend steam cleaning soft surfaces and carpets in the event of viral agents. This recommendation is inline with governments around the world.

The UK government recommends steam specifically against Covid-19.

How often should I clean?

Surfaces and frequently touched points should be steam sanitised every 24hours.

Should I use vacuum or just steam?

It is recommended that in most cases just steam or steam and microfibre is used. Special consideration can be given to use a vacuum in certain circumstances – in this case you should ONLY use vacuums with HEPA filtration.

Can steam be used on other surfaces?

Yes, our machines can be used on nearly any surface. Our dry steam cleaners and recommended microfibre cloths are being used as the sole cleaning method in hospitals within Australia and New Zealand. Combining these two cleaning technologies has seen a statistically significant improvement on achieving a reduction in hospital acquired infections and improved cleaning efficacy. These results are consistently inline with expectations regardless of the size or purpose of the facility, hospitals also consistently report a significant reduction in costs, cleaning times, staff fatigue and WHS claims as well as a significant improvement in visual and microbiological cleaning results.