PureBelt™️ Modular Conveyor Cleaning System:

Clean-in-Place Solution

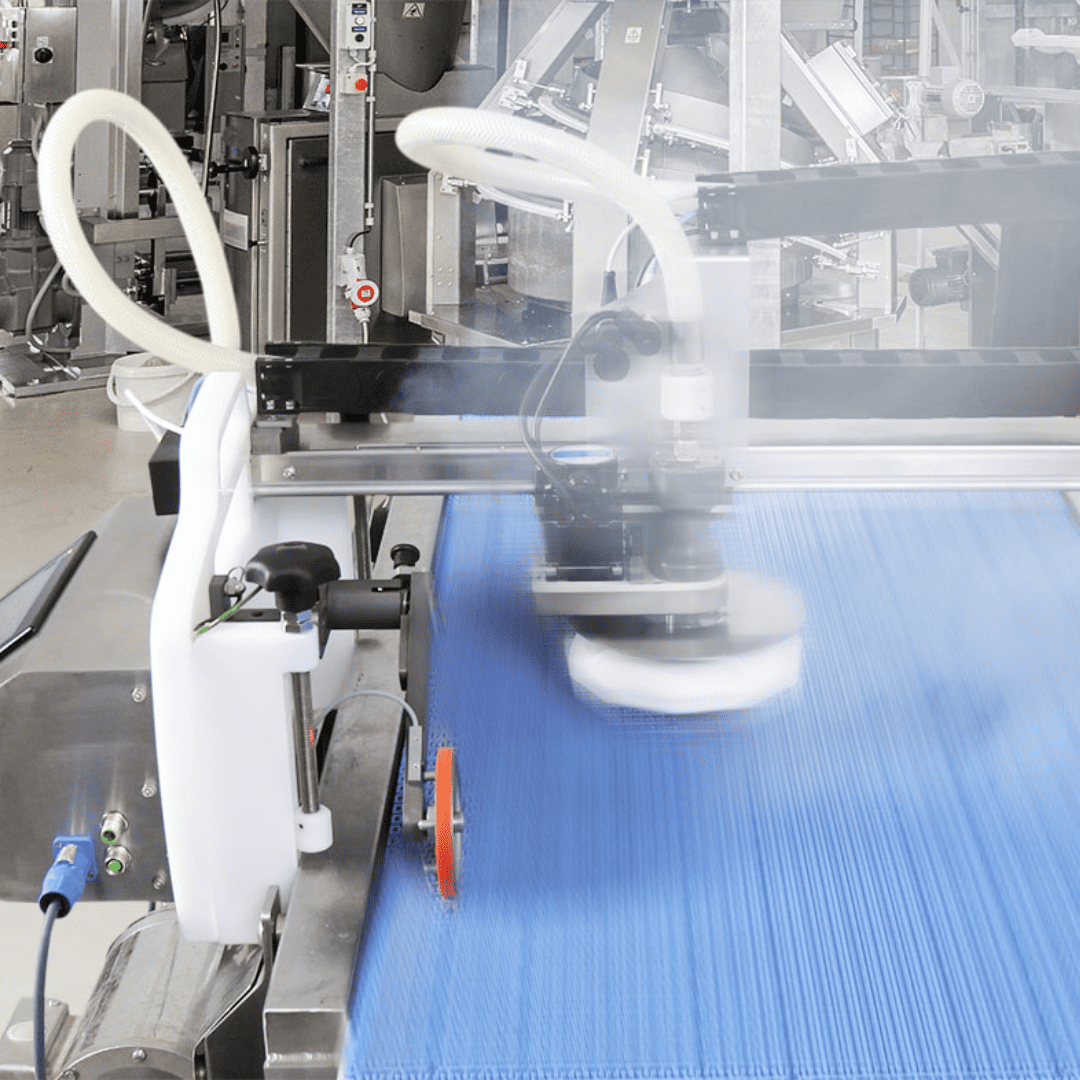

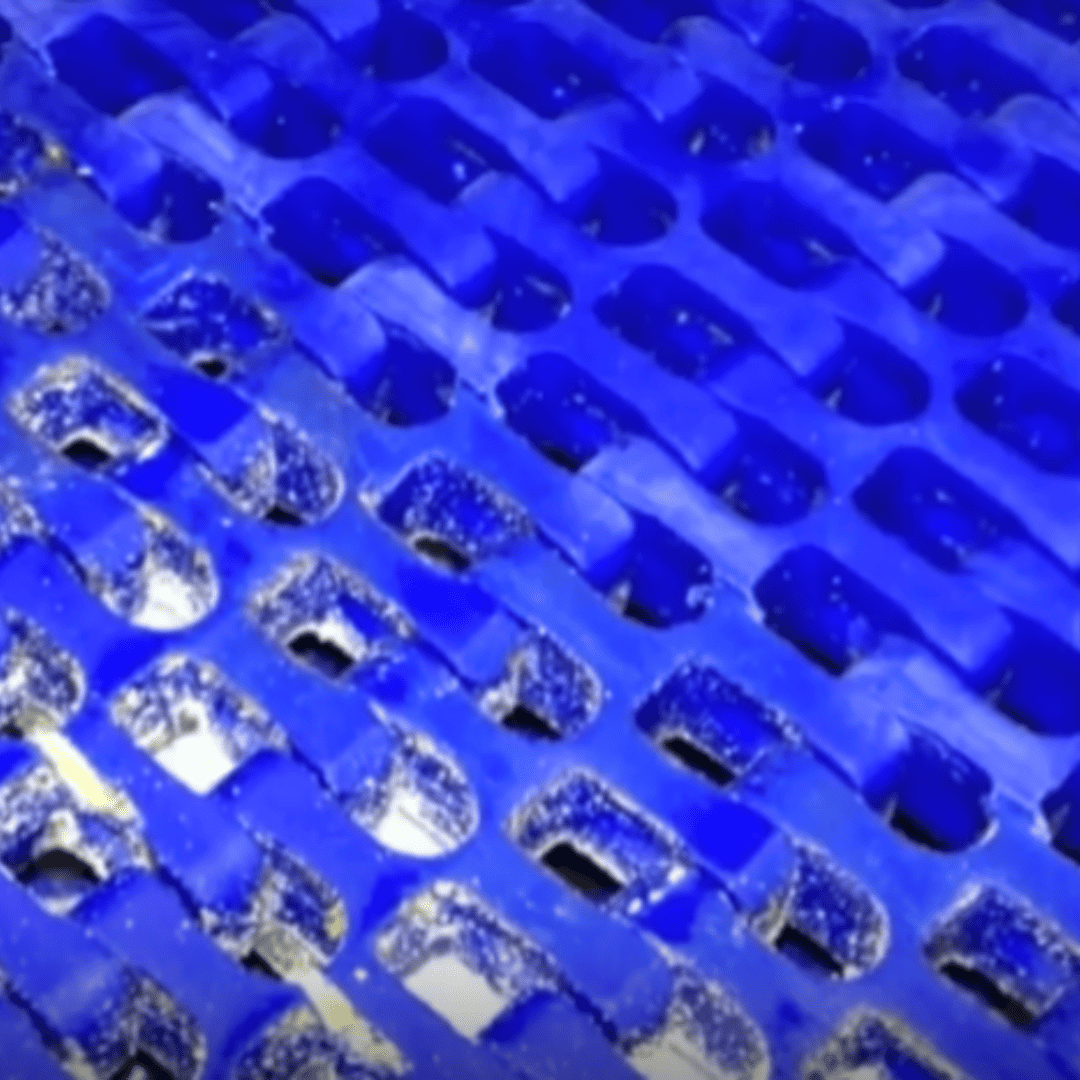

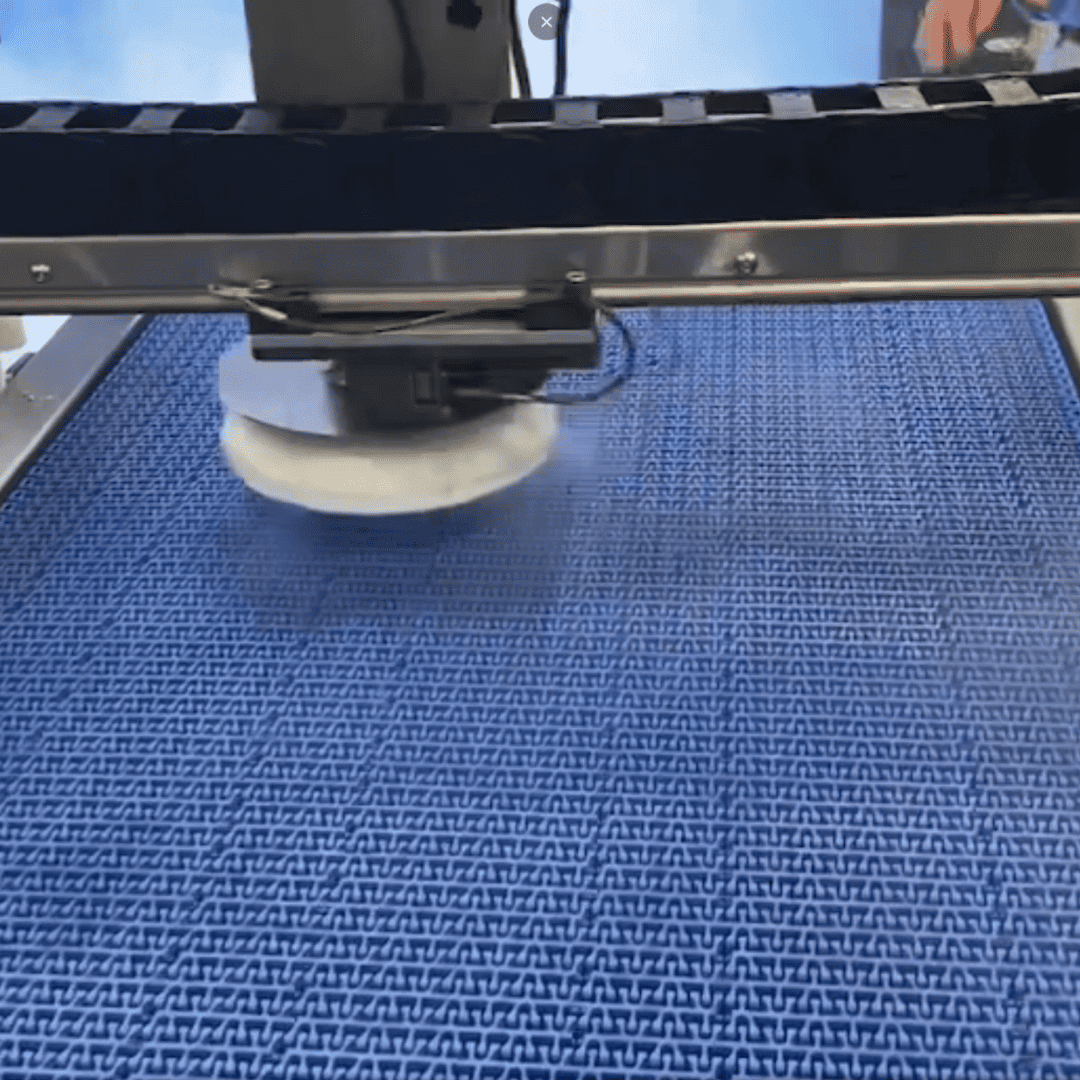

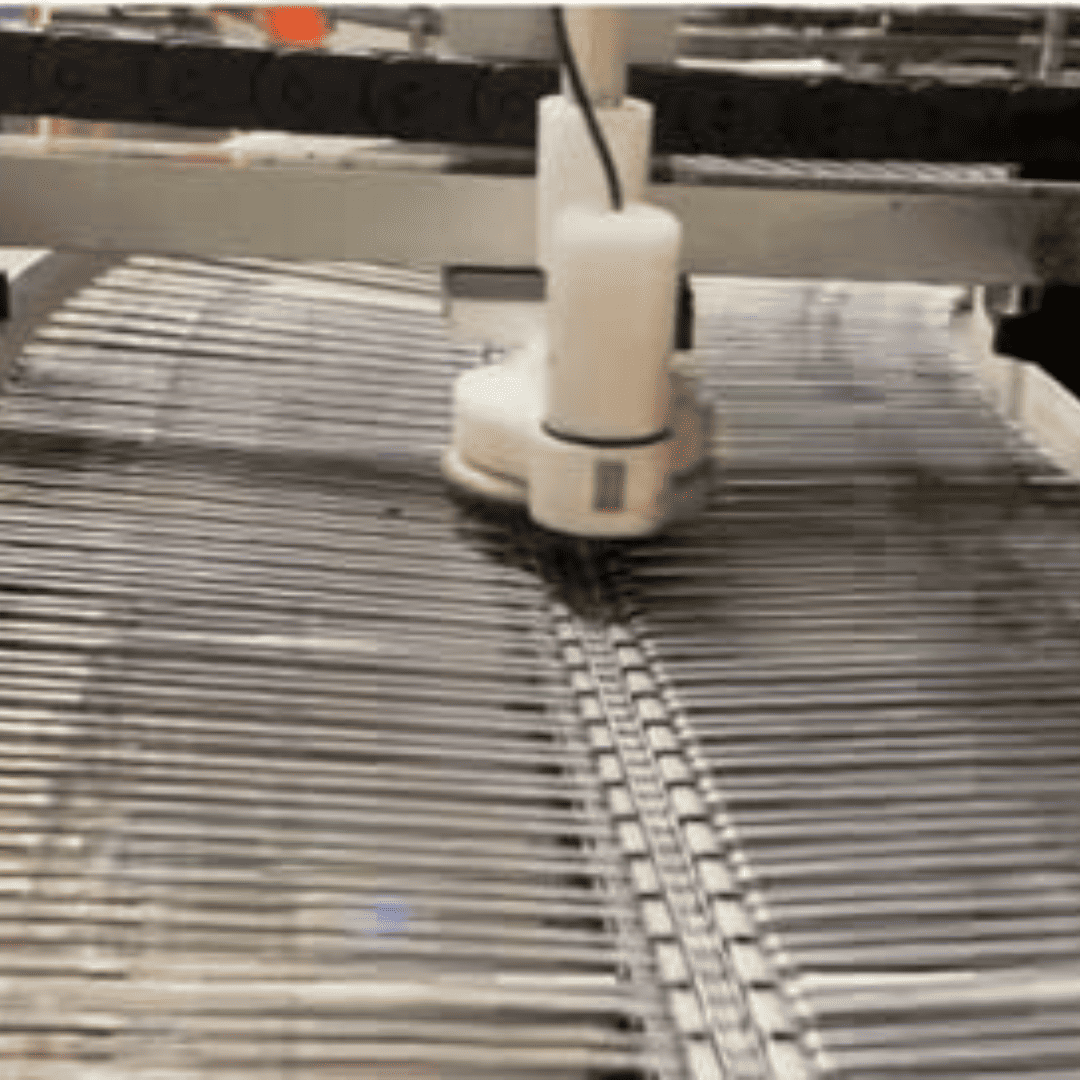

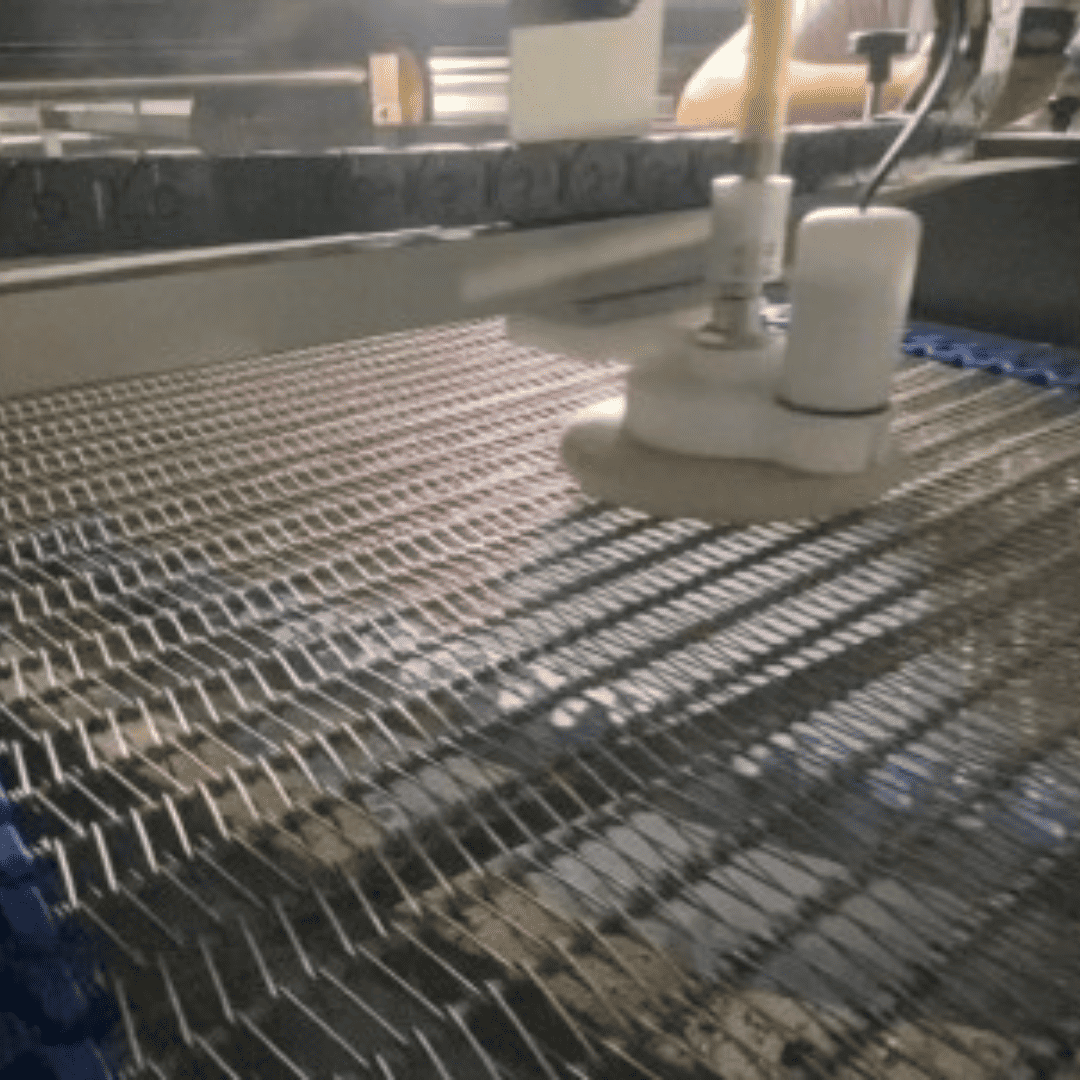

Introducing the patented PureBelt™ Modular Belt Cleaning System, a revolutionary conveyor belt cleaning technology for the food production and processing industry. This innovative system utilises high-temperature dry steam to effectively and safely clean mesh-style plastic or metal belts, whilst using 90% less water than other cleaning methods. Equipped with a cutting-edge spinning steam head, this system swiftly eliminates a wide range of contaminants such as soils, sugars, fats, mould and allergens, ensuring belts are ready for immediate production.

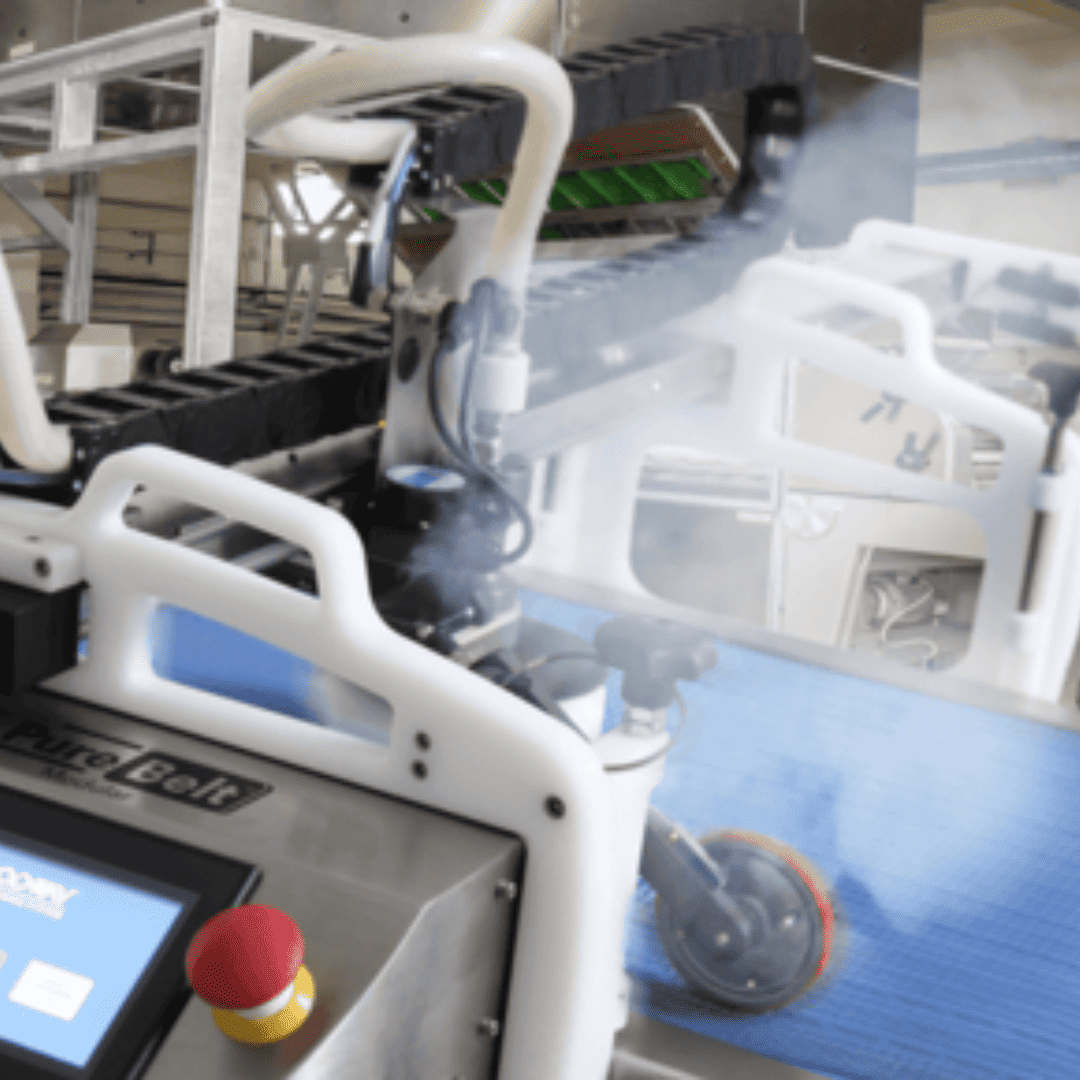

Its versatility allows it to be utilized across multiple belts in your facility, with custom solutions tailored to fit your specific conveyor dimensions. It is an ideal solution for belt cleaning in various settings, including commercial bakeries, confectionery plants, and other production facilities. Whether you need to clean spiral coolers, packaging lines, or other components, the Goodway PureBelt™ Modular System guarantees efficient and effective results, making it an invaluable asset in your operations. This system has proven its efficacy in eliminating yeast and mould from product contact surfaces, offering a comprehensive “dry cleaning” solution.

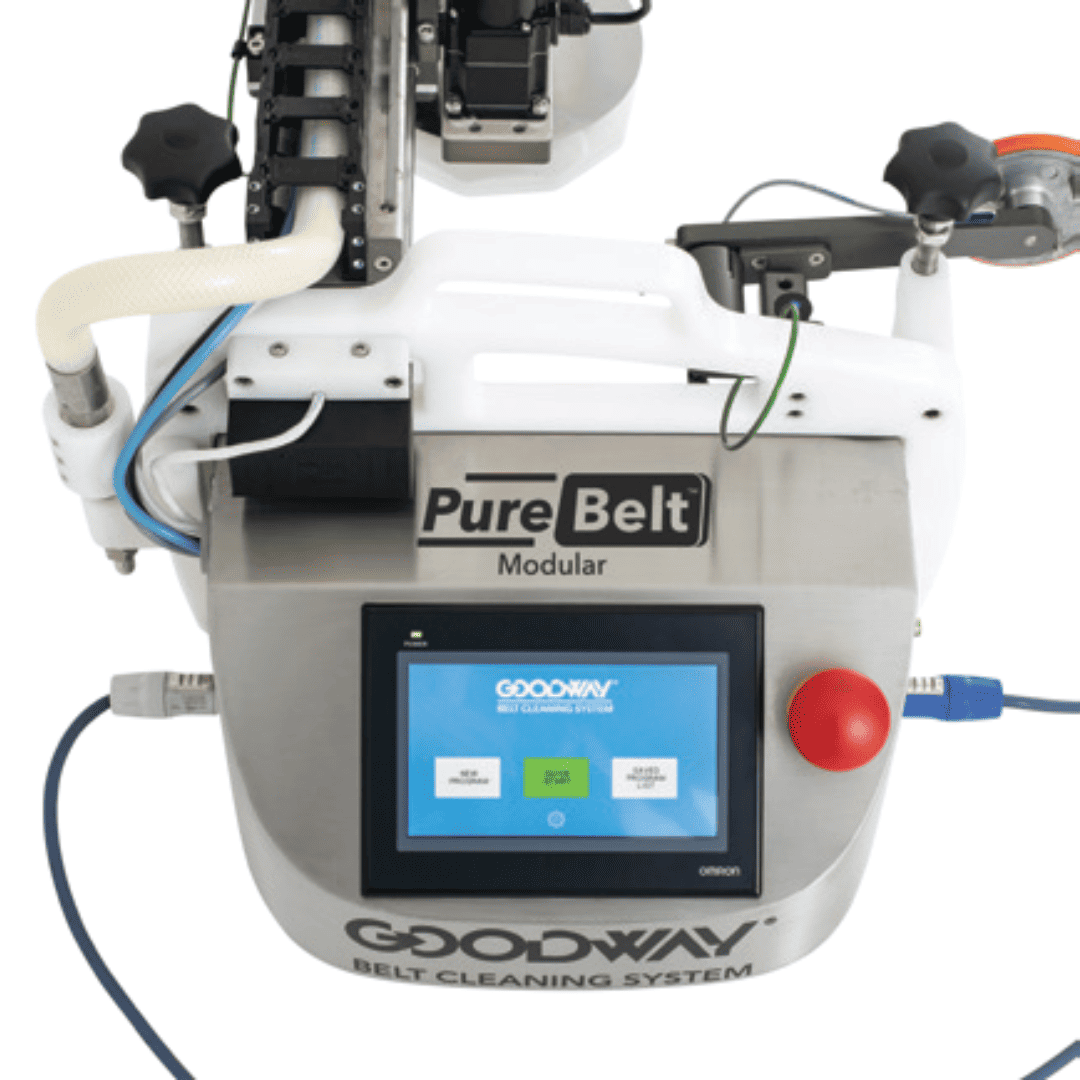

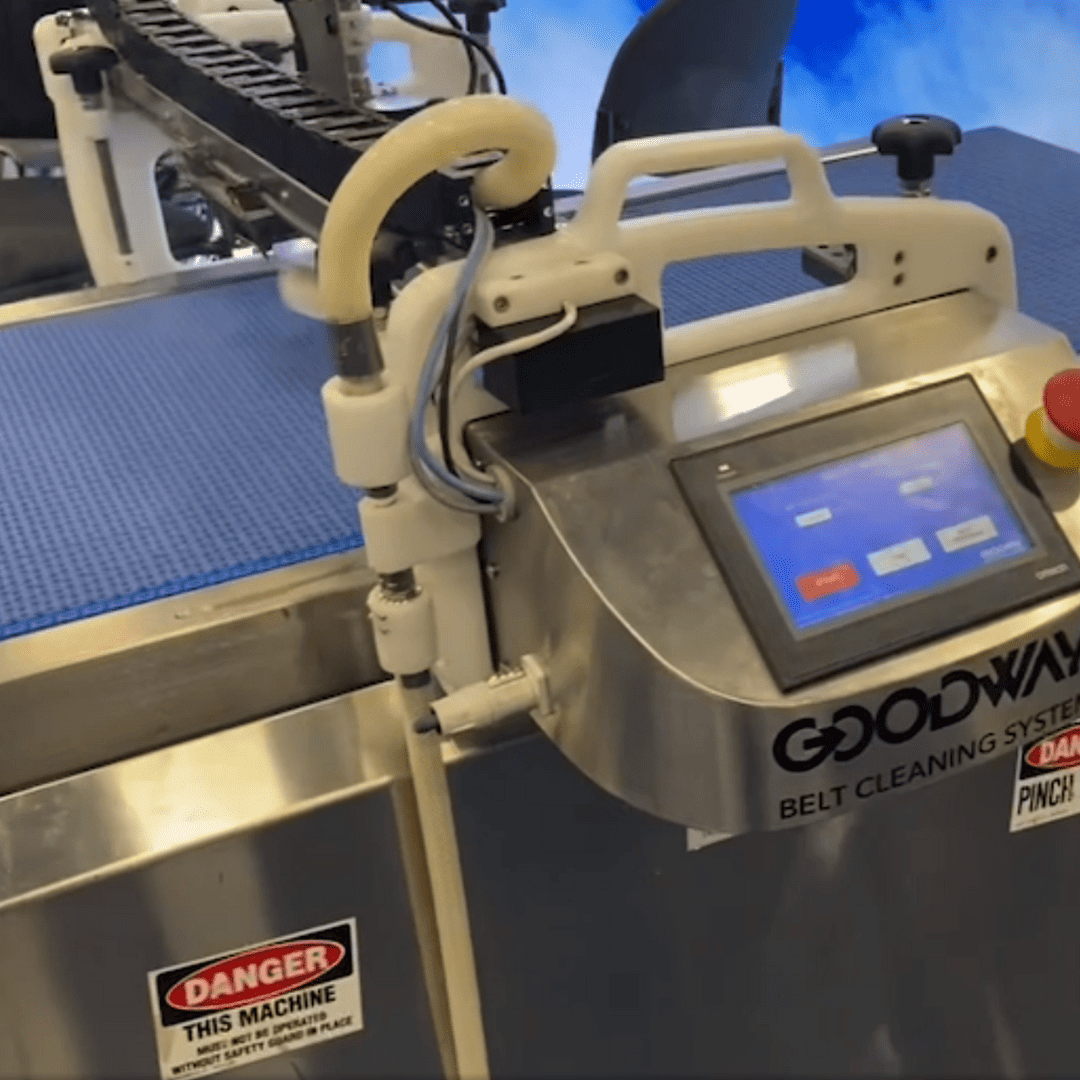

Intuitive Software Interface

The PureBelt™ modular cleaning system boasts an intuitive software interface, making it user-friendly and adaptable to your production facility’s belt types and product lines. With the ability to customise cleaning patterns and techniques, you can optimise the system’s performance to meet your unique requirements. The system is equipped with special sensors that automatically detect belt motion, enhancing cleaning efficiency based on conveyor belt speed.

PureBelt™️ Modular Conveyor Cleaning System:

Clean-in-Place Solution

Introducing the patented PureBelt™ Modular Belt Cleaning System, a revolutionary conveyor belt cleaning technology for the food production and processing industry. This innovative system utilises high-temperature dry steam to effectively and safely clean mesh-style plastic or metal belts, whilst using 90% less water than other cleaning methods. Equipped with a cutting-edge spinning steam head, this system swiftly eliminates a wide range of contaminants such as soils, sugars, fats, mould and allergens, ensuring belts are ready for immediate production.

Its versatility allows it to be utilized across multiple belts in your facility, with custom solutions tailored to fit your specific conveyor dimensions. It is an ideal solution for belt cleaning in various settings, including commercial bakeries, confectionery plants, and other production facilities. Whether you need to clean spiral coolers, packaging lines, or other components, the Goodway PureBelt™ Modular System guarantees efficient and effective results, making it an invaluable asset in your operations. This system has proven its efficacy in eliminating yeast and mould from product contact surfaces, offering a comprehensive “dry cleaning” solution.

Intuitive Software Interface

The PureBelt™ modular cleaning system boasts an intuitive software interface, making it user-friendly and adaptable to your production facility’s belt types and product lines. With the ability to customise cleaning patterns and techniques, you can optimise the system’s performance to meet your unique requirements. The system is equipped with special sensors that automatically detect belt motion, enhancing cleaning efficiency based on conveyor belt speed.

Reduce Labour Costs

Dry steam cleaning uses 90% less water than traditional cleaning methods. Dry steam removes soils like sugars, fats, oils, allergens, mould and more, leaving belts dry, sanitised and clean.

The Goodway PureBelt™ Modular Belt System is a unique conveyor belt cleaning system able to clean mesh-style plastic or metal belts. Reduce overall cleaning time, save on labour, decrease sanitation time, increase productivity with faster changeovers and extend production time. The Modular system is adjustable in width to facilitate use across multiple locations in the plant Leaving belts clean, dry, sanitised and allergen free.

Reduce Labour Costs

Dry steam cleaning uses 90% less water than traditional cleaning methods. Dry steam removes soils like sugars, fats, oils, allergens, mould and more, leaving belts dry, sanitised and clean.

The Goodway PureBelt™ Modular Belt System is a unique conveyor belt cleaning system able to clean mesh-style plastic or metal belts. Reduce overall cleaning time, save on labour, decrease sanitation time, increase productivity with faster changeovers and extend production time. The Modular system is adjustable in width to facilitate use across multiple locations in the plant Leaving belts clean, dry, sanitised and allergen free.

Product Features

Designed for cleaning mesh-style plastic or metal belts, the Goodway® PureBelt™ Modular Belt System is a fully portable cleaning system for use across multiple production lines. This system is available in customised sizes and is designed to deliver clean-in-place (CIP) cleaning of modular belts in dry clean environments like; bakeries, snack plants, confectionery plants, and sensitive industrial settings. The PureBelt™ Modular Belt System reduce production downtime and labour costs by automating conveyor belt cleaning.

USE FOR

FEATURES

Designed for cleaning mesh-style plastic or metal belts, the Goodway® PureBelt™ Modular Belt System is a fully portable cleaning system for use across multiple production lines. This system is available in customised sizes and is designed to deliver clean-in-place (CIP) cleaning of modular belts in dry clean environments like; bakeries, snack plants, confectionery plants, and sensitive industrial settings. The PureBelt™ Modular Belt System reduce production downtime and labour costs by automating conveyor belt cleaning.

USE FOR

FEATURES

FAQ's

Will the PureBelt™ Modular System clean belts in one pass?

Due to several factors, like speed or width, the number of passes can be determined with an on-site demonstration or consultation. Usually, smaller width belts can be cleaned with one or two passes. For larger width belts with stubborn soils or neglected belts, three to four passes are efficient.

Do I need a different Purebelt™ Modular System for each belt?

No, the portability and customizability of the Purebelt™ Modular System allow you to use the same system from your widest belt down to a 10″ belt.

Will dry steam damage the belt?

No, dry steam safely cleans mesh belting without any damage to the belt material.

Case Study: Food & Beverage Processing

A start-up tortilla manufacturer in Lawrence, New York, was looking for a way to clean their equipment efficiently and effectively in both production and packaging without having to rely heavily on using water.

The Challenge: Since their bakery is located on the second floor with another company directly below them, they are not able to clean using much water as they fear flooding the rooms directly underneath. They tried doing a controlled wet wash with a wet vacuum extracting all the water which resulted in a lot of hard labor hours. The attempt instilled apprehension in the sanitation team as not all the water was able to be successfully controlled and contained.

The Solution: Working with a Goodway Account Manager, they decided to invest in a Cosmos GVC-36000 dry steam cleaner. The Cosmos GVC-36000 uses only 7 gallons (26.5L) of water, has no chemicals, and is extremely low in moisture content.

The Result: The Cosmos GVC-36000 allowed them to clean all their equipment quickly and efficiently without the fear of flooding the floor below.

Case Study: Food & Beverage Processing

A start-up tortilla manufacturer in Lawrence, New York, was looking for a way to clean their equipment efficiently and effectively in both production and packaging without having to rely heavily on using water.

The Challenge: Since their bakery is located on the second floor with another company directly below them, they are not able to clean using much water as they fear flooding the rooms directly underneath. They tried doing a controlled wet wash with a wet vacuum extracting all the water which resulted in a lot of hard labor hours. The attempt instilled apprehension in the sanitation team as not all the water was able to be successfully controlled and contained.

The Solution: Working with a Goodway Account Manager, they decided to invest in a Cosmos GVC-36000 dry steam cleaner. The Cosmos GVC-36000 uses only 7 gallons (26.5L) of water, has no chemicals, and is extremely low in moisture content.

The Result: The Cosmos GVC-36000 allowed them to clean all their equipment quickly and efficiently without the fear of flooding the floor below.

By viewing this website, you acknowledge and agree that Goodway products, names, logos, and designs shown are protected by United States and international trademarks, patents, trade secrets and other intellectual property or proprietary rights owned of Crossford International LLC and contain and rely upon inventions, original works, and novel concepts developed or acquired by Crossford. All right, title and interest therein, as well as to any improvements, creations, developments, derivatives, or inventions thereto, shall remain vested solely in Crossford.